الشحن مجاني لكافة الطلبات فوق ال 2000 ريال في السعودية

Common VFD Failures in Water Pumping Systems and How to Handle Them

- not only pumps

- May 18, 2025

- 5:08 pm

Table of Contents

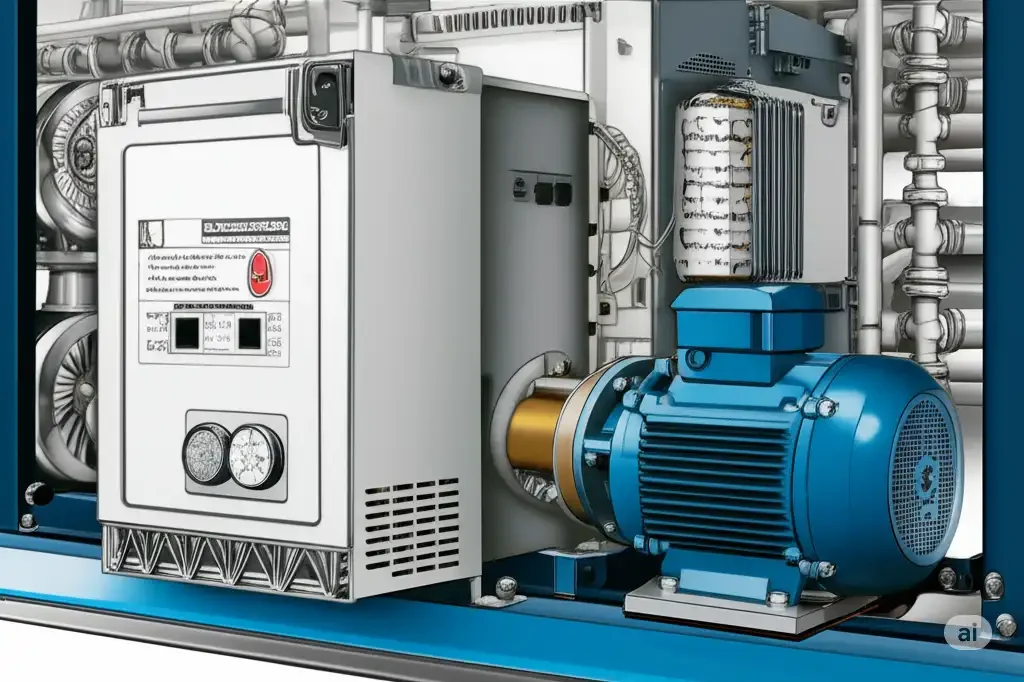

Variable Frequency Drives (VFDs) are essential components in modern water pumping systems. They enable smart control of motor speed and significantly improve energy efficiency. However, despite their many benefits, VFD failures remain one of the most common issues faced by engineers and technicians in the field. These faults can lead to full system shutdowns or significantly reduce the pump’s lifespan.

In this article, we’ll explore the most frequent VFD failures in pumping applications, their causes, and practical prevention methods — all backed by hands-on expertise.

Keep reading to avoid costly breakdowns and ensure your system keeps running at peak performance.

What Does a VFD Do in Water Pumping Systems?

A Variable Frequency Drive (VFD) controls the speed of electric motors, playing a crucial role in modern water pumping systems.

Rather than running pumps at full capacity all the time, VFDs adjust motor speed based on actual demand. This leads to:

- Improved Energy Efficiency: Reduces power waste during low-demand periods.

- Precise Flow Pressure Control: Enhances water flow accuracy, protecting pipes and system components.

- Reduced Mechanical Wear: Smooth motor operation minimizes mechanical shocks during start/stop cycles.

- Lower Operating and Maintenance Costs: Due to less strain on system components.

Yet, improper setup or misoperation of the VFD can cause sudden system failures — and that’s where the real challenges begin.

Common Causes of VFD Failures in Pumping Applications

1. Electrical Failures

Electrical issues are among the most frequent causes of VFD malfunctions. These may include:

- Voltage Fluctuations: Unstable voltage levels from the power source can damage internal VFD components.

- Overcurrent: Occurs when the current exceeds the VFD’s design capacity, often due to overloads or faulty components.

- Grounding Issues: Poor or improper grounding can disrupt signal stability, leading to erratic system behavior or shutdowns.

2. Mechanical Failures

Mechanical issues typically stem from problems in components connected to the VFD:

- Motor Problems: Overloading, wear, or bearing failure can impair proper motor function.

- Bearing Failures: Worn-out bearings can cause excessive vibration, leading to operational instability or total system failure.

3. System Configuration Errors

Sometimes, failures arise from non-electrical issues or incorrect system settings:

- Connection Issues: Loose or incorrect wiring can lead to abnormal current flow or system outages.

- Incorrect Settings: Misconfigured parameters, such as deceleration speed or load mismatches, can trigger system errors or shutdowns.

How to Prevent Common VFD Failures

Protecting your VFD system and ensuring efficient operation requires a proactive approach. Here are key preventative strategies:

1. Routine Maintenance

Regular maintenance is essential for early fault detection and prevention:

- Component Inspections: Check wires, motors, and circuits for signs of wear or damage.

- Cleaning: Keep the VFD clean from dust and debris to prevent overheating.

- Timely Replacement: Replace worn parts before they cause unexpected breakdowns.

2. Continuous Staff Training

Proper handling starts with knowledgeable personnel:

- Fault Recognition Training: Train staff to quickly identify and respond to common issues.

- Settings Configuration: Ensure technicians know how to properly set deceleration speeds, current limits, etc.

- Promote Preventive Culture: Encourage best practices, like avoiding motor overloads and monitoring component health.

3. Proper VFD Setup

Correct settings are vital for system stability:

- Deceleration Speed: Adjust to ensure gradual motor stops, preventing harmful energy spikes.

- Overcurrent Protection: Use built-in protections to avoid damage from sudden surges.

- Routine Settings Review: Periodically review and adjust settings to align with system demands.

System Protection Strategies in Pumping Applications

To enhance system longevity and reliability, adopt these smart strategies:

1. Improve Operating Environment

Environmental conditions directly affect VFD performance:

- Optimal Temperature Range: Maintain ambient temperature within manufacturer recommendations.

- Humidity & Ventilation: Ensure adequate airflow to prevent heat buildup and moisture accumulation.

- Dust Protection: Install VFDs in clean, well-ventilated enclosures to avoid component damage.

2. Smart Monitoring

Real-time performance tracking can prevent major issues:

- Performance Monitoring Tools: Use smart meters or control systems to continuously track voltage, current, speed, and temperature.

- Data Analytics & Predictive Maintenance: Analyze trends to forecast potential failures before they happen.

- Early Warning Systems: Configure alerts for abnormal readings, giving technicians time to intervene.

3. Rapid Response Protocols

Minimize downtime with effective emergency preparedness:

- Spare Parts Readiness: Keep essential components like motors and filters on hand for quick replacement.

- Emergency Plans: Establish step-by-step procedures for addressing common faults and failures.

- On-the-Job Training: Regularly simulate real failure scenarios to keep staff prepared.

Advanced Techniques to Boost VFD Efficiency and Reliability

To maximize VFD performance and system uptime, consider integrating modern technologies with preventive care:

1. Modern Efficiency Technologies

- Load Monitoring Systems: Smart load-tracking tools help optimize energy use and prevent inefficiencies.

- Signal Filters: High-performance filters enhance signal quality and reduce electromagnetic interference, improving system stability.

2. Preventive Maintenance Practices

- Scheduled Inspections: Establish a consistent preventive maintenance schedule for testing, cleaning, and part replacement.

- Settings Audit: Regularly verify operational parameters (e.g., deceleration speed, voltage limits) against system requirements.

- Firmware Updates: Keep VFD software up to date to leverage the latest efficiency and protection features.

Final Thoughts

In this article, we’ve covered the most common VFD issues in water pumping systems, their causes, and how to prevent them through routine maintenance, proper configuration, and continuous staff training.

We also explored essential strategies for long-term system integrity, including optimizing the operating environment, smart monitoring, and emergency preparedness — along with modern efficiency tools like load tracking and advanced filtering.

By embracing proactive maintenance and modern technology, your VFD system can perform more reliably, efficiently, and with fewer unexpected disruptions.

Looking for trusted solutions for your pumping and maintenance needs?

At NOP, we’re here to help. Contact our expert team via WhatsApp or follow us on Instagram at Advanced Pumps | NOT ONLY PUMPS for more expert advice and technical insights.

At NOP, we’re committed to delivering top-tier solutions that keep your systems running smoothly and efficiently.

احصل على عرض سعر مشروع

من نحن

شركة المضخات المتقدمة NOP، تأسست عام 2007 في الرياض، السعودية، لتقديم حلول مبتكرة في مجال المضخات. مع توسعنا المستمر، افتتحنا فروعاً في جدة، الدمام، وتبوك لتوفير خدمات أسرع ودعم فني متميز. مقرنا الرئيسي في حي العمل، شارع عمر المختار بالرياض.