الشحن مجاني لكافة الطلبات فوق ال 2000 ريال في السعودية

Centrifugal Pump Failures: Causes, Warning Signs & Effective Solutions

- not only pumps

- May 25, 2025

- 7:26 pm

Table of Contents

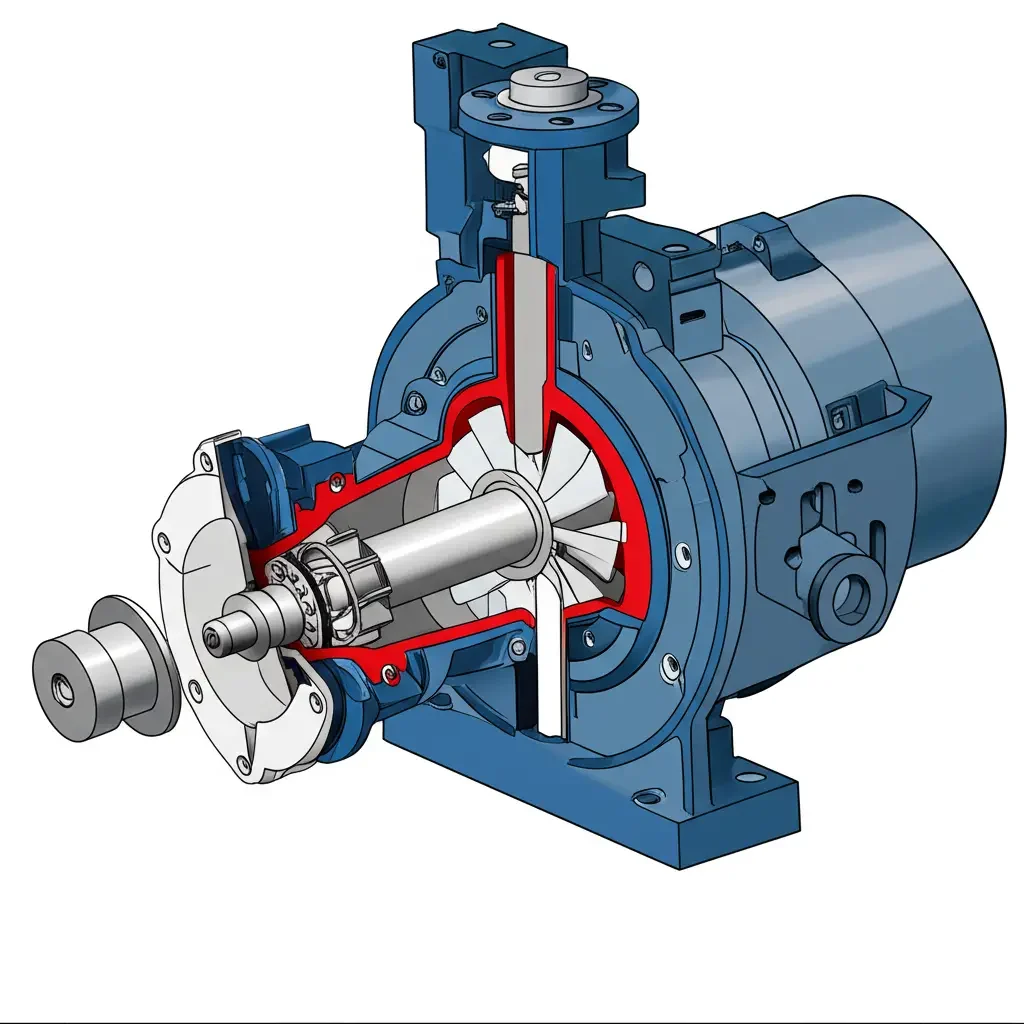

Centrifugal pumps are vital components in water supply systems, cooling networks, and various industrial applications. Despite their efficiency and durability, they can experience sudden failures that disrupt operations and increase maintenance costs.

In this article, we’ll explore the most common centrifugal pump failures, their early warning signs, and professional ways to handle them—helping you minimize risk and extend your pump’s lifespan.

What is a Centrifugal Pump?

A centrifugal pump uses rotational energy from an impeller to move fluids. Known for their simplicity and high efficiency, these pumps are widely used in:

- Water and wastewater networks

- HVAC and cooling systems

- Chemical and petroleum industries

However, like any mechanical device, poor maintenance or improper operation can lead to pump failures.

Common Centrifugal Pump Failures and How to Detect Them

1. Pump Fails to Start (Sudden Stop)

Description:

One of the most frequent issues is the pump not starting, despite electrical power being available.

Possible Causes:

- Weak or damaged power supply cables

- Motor failure

- Internal blockage or foreign object obstructing the impeller

How to Detect:

Use a megger to test motor insulation

Inspect electrical connections and voltage

Manually test impeller rotation after power is off

2. Unusual Noise and Vibrations

Description:

New or strange noises and vibrations are early signs of internal mechanical problems.

Possible Causes:

- Cavitation due to insufficient fluid intake

- Bearing (ball bearing) wear

- Misalignment between the motor and pump

How to Detect:

- Use vibration detection equipment

- Perform regular vibration analysis

- Visually inspect alignment and bolt tightness

3. Weak or No Flow

Description:

Reduced or no liquid flow despite the pump running.

Possible Causes:

- Blocked impeller or piping

- Air leakage in the suction line

- Reverse impeller rotation

How to Detect:

- Check the flow meter

- Test the motor’s rotation direction

- Inspect the impeller for blockage or damage

4. Overheating of Pump or Motor

Description:

One of the most dangerous failures—heat buildup can destroy critical components.

Possible Causes:

- Pump overload

- Inadequate bearing lubrication

- Blocked cooling system

How to Detect:

- Use an infrared thermometer

- Monitor electric current for spikes

- Inspect the ventilation and cooling system

4. Overheating of Pump or Motor

Description:

One of the most dangerous failures—heat buildup can destroy critical components.

Possible Causes:

- Pump overload

- Inadequate bearing lubrication

- Blocked cooling system

How to Detect:

- Use an infrared thermometer

- Monitor electric current for spikes

- Inspect the ventilation and cooling system

Preventive Maintenance: The Key to Pump Reliability

Preventive maintenance is essential—not optional—to reduce failure risks and keep your pump operating efficiently. It starts with daily visual inspections to identify leaks, unusual vibrations, or temperature changes. Even listening to the pump during operation can reveal early symptoms.

Key Maintenance Practices:

- Scheduled lubrication of bearings without over-greasing

- Precision alignment between motor and pump using laser tools

- Impeller cleaning and inspection for wear or deposits

- Seal integrity checks to catch leaks early

- Performance logging of flow rate, pressure, and energy use

- Spare part readiness, especially seals and bearings

By following these steps, centrifugal pump failures can be significantly reduced—resulting in lower operating costs and higher system reliability.

Why Do Centrifugal Pumps Fail?

Even the toughest centrifugal pumps are prone to failure if not operated or maintained correctly. Most failures can be prevented through awareness and best practices.

Top Causes of Pump Failures:

1️⃣ Improper Operation

Running the pump dry, using incorrect speed, or starting with an empty suction line can damage internal components.

2️⃣ Lack of Routine Maintenance

Skipping routine tasks like lubrication, cleaning, or seal replacement causes minor issues to become major failures.

3️⃣ Cavitation

Occurs when suction pressure is too low, forming bubbles that collapse inside the pump—damaging metal surfaces.

4️⃣ Misalignment

Even slight misalignment between the motor and pump leads to constant vibration, bearing wear, and shaft cracks.

5️⃣ Design or Installation Flaws

Using the wrong pump for the application or installing it incorrectly can cause inefficiencies and breakdowns.

6️⃣ Ignoring Early Warning Signs

Unusual noises, high temperatures, or sudden flow drops are clear alerts. Ignoring them accelerates failure.

7️⃣ Poor Fluid Quality

Liquids with abrasive solids or corrosive chemicals wear down impellers and seals—frequent causes of damage.

In most cases, pumps don’t fail suddenly—they give warning signs. A trained engineer can catch these signs early and prevent catastrophic downtime.

NOP Expert Advice: Knowledge Before Repair

Don’t wait for failure to start analyzing your pump.

Pumps don’t collapse out of nowhere—they whisper, then speak, before they finally scream with a major breakdown. A smart engineer hears the whispers first.

At NOP (Not Only Pumps), we don’t just offer solutions—we invest in education.

Because a quick fix solves the problem once, but knowledge prevents it from ever happening.

When an engineer understands how the pump “behaves,” detects subtle changes, and connects system dynamics with performance indicators—they’re always two steps ahead of a potential failure.

We teach you to think like a pump, and to detect failures before they happen.

Whether you’re working at a power plant, factory, or water network—managing centrifugal pump failures starts with:

✅ Advanced hands-on training

✅ Indicator-based inspections (not routine-based)

✅ A deep understanding of system-pump interaction

Whether you’re working at a power plant, factory, or water network—managing centrifugal pump failures starts with:

✅ Advanced hands-on training

✅ Indicator-based inspections (not routine-based)

✅ A deep understanding of system-pump interaction

📞 Need technical support or have questions?

Message us directly on WhatsApp – [Click here to contact us]

📲 Follow us on Instagram for updates and technical tips:

Advanced Pumps | NOT ONLY PUMPS

We’re here to be your partner—every step of the way toward higher performance and more reliable pumping systems.

احصل على عرض سعر مشروع

من نحن

شركة المضخات المتقدمة NOP، تأسست عام 2007 في الرياض، السعودية، لتقديم حلول مبتكرة في مجال المضخات. مع توسعنا المستمر، افتتحنا فروعاً في جدة، الدمام، وتبوك لتوفير خدمات أسرع ودعم فني متميز. مقرنا الرئيسي في حي العمل، شارع عمر المختار بالرياض.