الشحن مجاني لكافة الطلبات فوق ال 2000 ريال في السعودية

Why Choosing Dual Mechanical Seals Can Save Your Pump System

- not only pumps

- June 2, 2025

- 12:03 pm

Table of Contents

In the world of industrial pumping, dual mechanical seals are among the most critical technologies for protecting pump systems and extending their service life. When handling abrasive or viscous fluids, standard sealing solutions often wear out quickly, leading to unexpected downtime and costly repairs. That’s why choosing the right mechanical sealing system is a vital step in ensuring consistent performance and operational efficiency in your facility.

Looking to avoid expensive breakdowns and keep your pumps running at peak performance? Discover how dual mechanical seals can be the ideal solution for your system.

What Are Mechanical Seals, and Why Do They Matter?

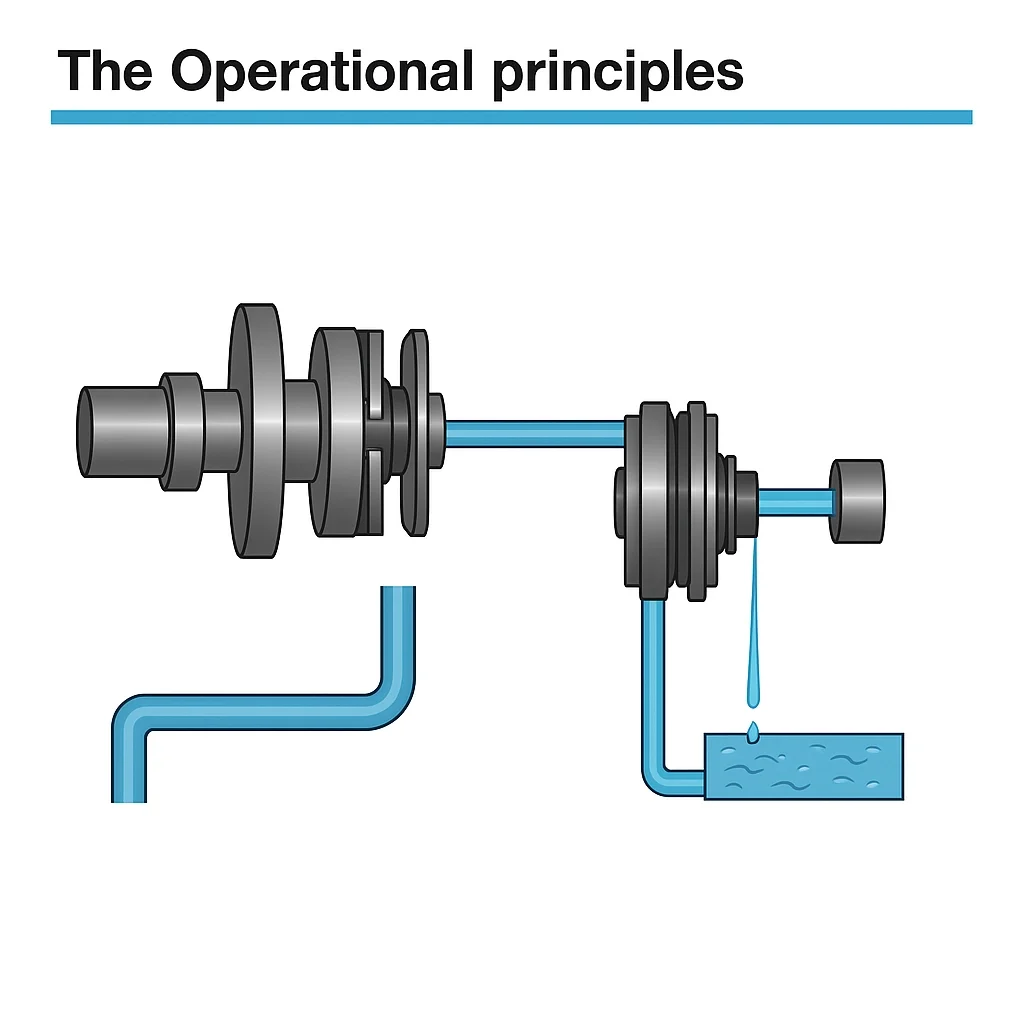

Mechanical seals are essential components of any pump system. They prevent fluid from leaking along the rotating shaft, sealing the gap between the rotating shaft and the stationary pump housing. By doing so, they not only keep the fluid contained but also block contaminants like dust or debris from entering the pump.

Their importance lies in maintaining operational efficiency, reducing unplanned downtime, and protecting your equipment. Without a reliable seal, your pump is vulnerable to fluid leakage, equipment failure, and substantial maintenance costs.

This is especially true when working with challenging fluids. Selecting the right type of mechanical seal—particularly for harsh environments—is a foundational step to ensure long-term reliability and efficiency.

When Is a Single Mechanical Seal Enough?

For standard, non-hazardous fluids, a single mechanical seal is often sufficient. These seals rely on a very thin fluid film that forms between the sealing faces due to pressure and centrifugal force, providing continuous lubrication and cooling.

This lubrication reduces friction and wear, making single seals a cost-effective and reliable solution in normal operating conditions.

However, if the pumped fluid contains abrasive solids or is highly viscous, single seals may not be up to the task. In these situations, the seal can quickly erode or become clogged, leading to premature failure and requiring a more advanced sealing solution—such as a dual mechanical seal.

The Challenge with Abrasive and Viscous Fluids

When pumps are used to handle abrasive or viscous fluids, single mechanical seals face significant challenges. Abrasive particles can rapidly wear down the seal faces due to constant friction, reducing their ability to contain the fluid and increasing the risk of sudden breakdowns.

Viscous fluids, on the other hand, may harden or deposit between the seal faces during downtime, causing the seal to “stick” or fail upon restart. This kind of failure can result in unplanned shutdowns, increased repair costs, and operational delays.

That’s where dual mechanical seals come in — offering a more robust solution for demanding applications.

How Dual Mechanical Seals Solve These Issues

Dual mechanical seals are specifically designed to handle difficult fluids like abrasives and viscous media. They feature two sets of sealing faces with a barrier fluid in between — a pressurized liquid compatible with the operating environment.

This barrier fluid isolates the seal faces from the process fluid, preventing direct contact with damaging particles and reducing wear. It also provides continuous cooling and lubrication, enhancing the performance and longevity of the seal.

To function correctly, the barrier fluid must be pressurized to at least 1 bar (15 psi) higher than the internal pump pressure. This is achieved using specialized systems such as thermosiphon loops or regulated water supply systems.

With dual seals, you significantly reduce the risk of failure, boost system reliability, and maintain performance in even the harshest industrial conditions.

Why Barrier Fluid Pressure Is Critical

For dual seals to perform optimally, maintaining correct barrier fluid pressure is essential. The pressure must be higher than the process fluid pressure to prevent contaminants from entering the seal chamber and to ensure that lubrication and cooling are maintained.

This is typically managed through:

- Thermosiphon systems, which rely on natural temperature-driven circulation to maintain pressure.

- Regulated water systems, which deliver consistent and controlled pressure to the seal chamber.

By ensuring the barrier fluid stays within the optimal pressure range, you extend seal life, minimize wear, and increase the overall efficiency of your pump system.

Choosing the Right Mechanical Seal with Advanced Pumps Co

Selecting the right mechanical seal is key to ensuring reliable and efficient pump performance. At Advanced Pumps Co, we recommend following these best practices:

- Understand your fluid: Know your medium’s properties — viscosity, presence of abrasives, chemical composition — to choose a compatible seal type.

- Assess operating conditions: Pressure, temperature, and shaft speed all influence the design and materials needed for your seal.

- Match the seal to the application: For clean, low-risk fluids, a single seal may suffice. For abrasive or viscous fluids, a dual mechanical seal with proper cooling and pressurization is the better choice.

- Use high-quality materials: Invest in seals made from wear-resistant and heat-tolerant materials for longer life and consistent performance.

- Consult the experts: Our team at Advanced Pumps Co is here to guide you in selecting, installing, and maintaining the ideal mechanical sealing solution for your needs.

These simple steps will help you reduce maintenance costs and increase the uptime and reliability of your pumping systems.

Don’t Leave Your System at Risk

In industrial pumping applications, choosing the right mechanical seal isn’t just a technical detail—it’s a strategic decision that protects your equipment and keeps operations running smoothly.

At Advanced Pumps Co, our dual mechanical seals are engineered to meet the toughest demands, offering superior protection and long-term performance in challenging environments.

Don’t wait until your system fails. Reach out to us today on WhatsApp for a free technical consultation tailored to your industry needs. And don’t forget to follow us on Instagram at Advanced Pumps | NOT ONLY PUMPS for the latest innovations and solutions.

Make a smart, engineering-driven decision — and keep your pumps performing at their best with NOP.

احصل على عرض سعر مشروع

من نحن

شركة المضخات المتقدمة NOP، تأسست عام 2007 في الرياض، السعودية، لتقديم حلول مبتكرة في مجال المضخات. مع توسعنا المستمر، افتتحنا فروعاً في جدة، الدمام، وتبوك لتوفير خدمات أسرع ودعم فني متميز. مقرنا الرئيسي في حي العمل، شارع عمر المختار بالرياض.