الشحن مجاني لكافة الطلبات فوق ال 2000 ريال في السعودية

Soft Starter vs Inverter: How to Choose the Best Solution for Pump Systems

- not only pumps

- June 11, 2025

- 3:21 pm

Table of Contents

When it comes to water pumping systems, selecting the right technology is critical for optimizing performance and minimizing downtime. Engineers and technicians often face a key question:

Soft Starter vs Inverter—which is better suited for your application?

In this guide, we’ll help you make an informed decision that balances efficiency, reliability, and long-term value.

Why the Soft Starter vs Inverter Decision Matters

The choice between a soft starter and an inverter (VFD) directly impacts:

- System performance

- Equipment lifespan

- Operational and maintenance costs

🔸 Soft Starter

- Best for: Applications requiring only reduced starting current (e.g., fixed-speed pumps, compressors).

- Benefits:

- Limits mechanical/electrical stress during startup.

- Reduces inrush current by up to 70%.

- Ideal for systems with constant-speed operation.

- Limitations:

- No speed control or energy savings during runtime.

🔸 Inverter (VFD)

- Best for: Dynamic control of speed and torque.

- Benefits:

- Energy savings in variable-load applications.

- Seamless integration with PLCs, SCADA, and automation.

- Advanced protections (phase loss, overload, short-circuit).

- Limitations:

- Higher upfront cost and complexity.

Your choice determines:

✔ System efficiency

✔ Energy consumption

✔ Maintenance costs

✔ Future adaptability

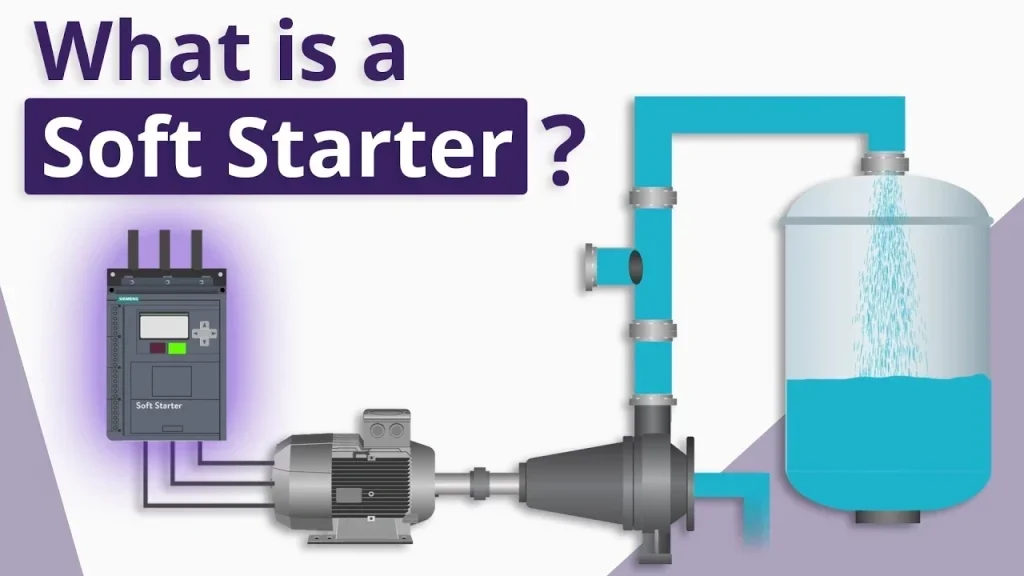

Soft Starters: How They Work & When to Use Them

A soft starter gradually reduces the motor’s starting current, protecting the system from sudden electrical/mechanical shocks.

How It Works:

- Uses SCRs to ramp up voltage smoothly.

- Bypasses to full voltage once the motor reaches rated speed.

Advantages:

- Up to 70% lower starting current.

- Protects mechanical components (e.g., couplings, belts).

- Ideal for fixed-speed pumps and compressors.

⚠ When to Avoid:

- Applications needing continuous speed control.

- Systems with frequent load variations.

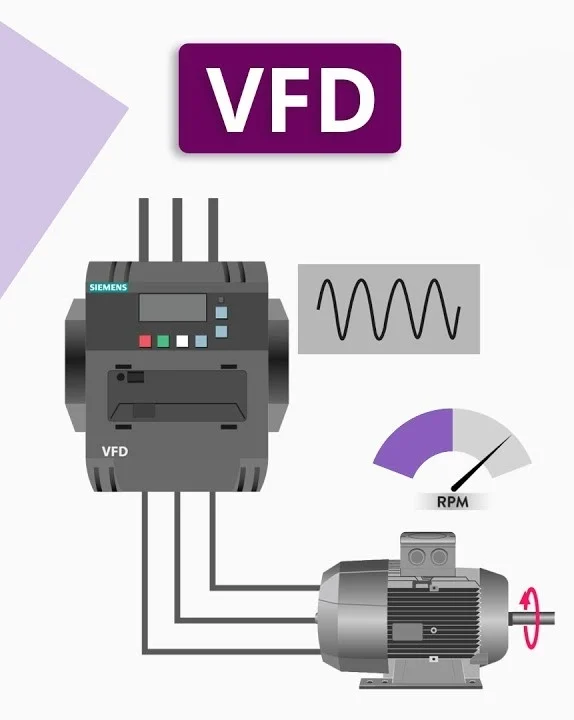

Inverters (VFDs): Full Control & Efficiency

A Variable Frequency Drive (VFD) adjusts motor speed and torque by varying voltage and frequency.

How It Works:

- Converts AC to DC, then back to adjustable AC.

- Maintains torque via V/f ratio control.

Advantages:

- Precise speed/torque control.

- Energy savings in variable-load systems.

- Smart sensor compatibility (pressure, flow, etc.).

- Advanced braking in some models.

⚠ When to Avoid:

- Simple, fixed-speed applications.

- Budget constraints (higher initial cost).

Side-by-Side Comparison

| Inverter (VFD) | Soft Starter | Criteria |

| Continuous adjustment | Startup only | Speed Control |

| Higher initial investment | Lower upfront | Cost |

| Significant (variable loads) | Minimal | Energy Savings |

| More advanced | Simple maintenance | Complexity |

| Variable-speed systems | Fixed-speed pumps | Best For |

Which One Should You Choose?

✅ Pick a Soft Starter If:

- Your system runs at fixed speed (e.g., large centrifugal pumps).

- You need affordable, simple protection during startup.

✅ Pick an Inverter (VFD) If:

- You require dynamic speed control.

- Energy efficiency and automation integration are priorities.

Cost Analysis: Think Long-Term

- Soft Starter: Lower initial cost, but no runtime savings.

- Inverter: Higher upfront price, but ROI through energy savings (especially in variable loads).

Why Trust Advanced Pumps?

At Advanced Pumps, we combine local expertise (Saudi Arabia) with global solutions. We don’t just sell equipment—we deliver tailored advice to ensure your system runs sustainably and efficiently.

Final Insight

The Soft Starter vs Inverter decision isn’t just about hardware—it’s a strategic choice for reliability and operational excellence.

📞 Get Expert Advice Today!

📲 WhatsApp: [Contact Link]

📷 Instagram: Advanced Pumps | NOT ONLY PUMPS

🚀 Choose Intelligence Over Assumptions—with Advanced Pumps.

احصل على عرض سعر مشروع

من نحن

شركة المضخات المتقدمة NOP، تأسست عام 2007 في الرياض، السعودية، لتقديم حلول مبتكرة في مجال المضخات. مع توسعنا المستمر، افتتحنا فروعاً في جدة، الدمام، وتبوك لتوفير خدمات أسرع ودعم فني متميز. مقرنا الرئيسي في حي العمل، شارع عمر المختار بالرياض.